DESIGN

DESIGN VISION

Cross-Pollination

My design practice has always focused on cross-pollination of engineering and design principles across industries. It brings in great value and keeps costs of research and innovating low.

50% Rule

I have always loved the 50% rule, where a new product should not ideally have more than 50% new technology in it. It keeps the project costs low, and reliability high. Every product does not need to be disruptive – but it needs to work every time.

Simplest, not Minimalist

I recognize that there is a difference between Simple and Minimal. Trendy does not mean its the only correct way of doing it, and minimalist does not always mean its simple.

DESIGN & DEVELOPMENT EXAMPLES

Medical Devices

Case Study: Medical Device for blood flow stimulation

Complete design and engineering of the device, involving ideation, prototyping, and design for manufacturing of plastics. Custom circuit board developed. Product uses a mix of hard and rubberized plastics complying with ISO10993 standards. This is an example of a commercially produced product where a wide range of skills including industrial design, electronic and materials engineering was used to develop the product.

Open Frame Test Setups

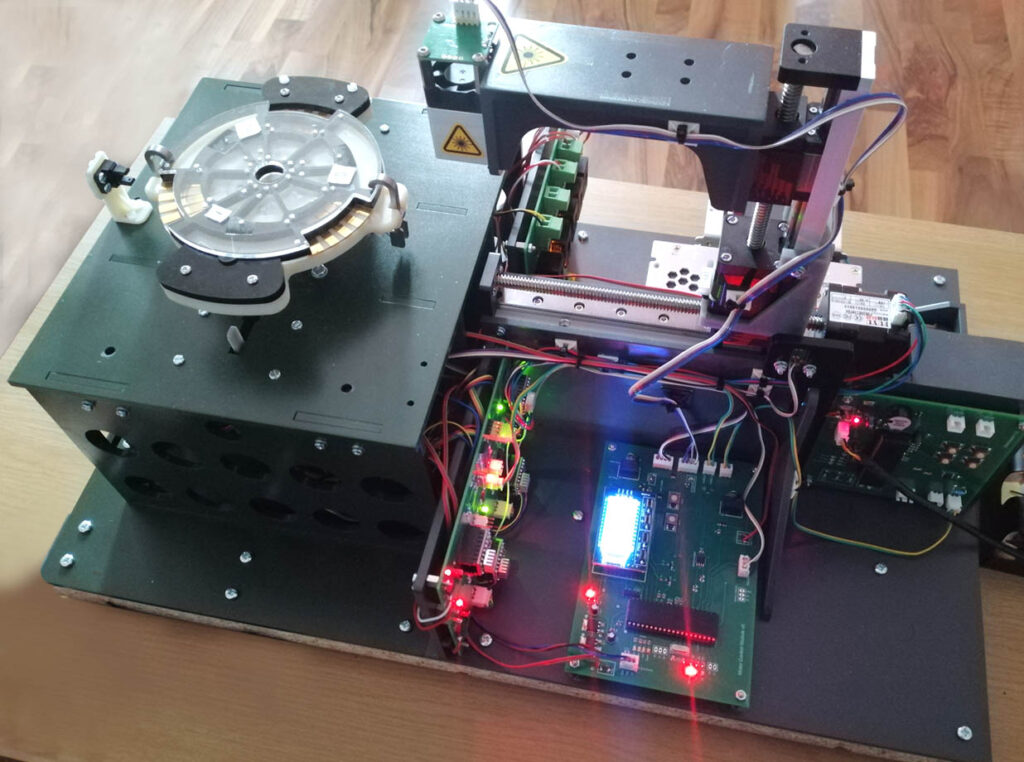

Case Study: Microfluidic Analyzer

Open frame build of an analyzer using 2 axis laser head, high speed servo motor, automatic lock and release system for test cartridge. All circuit boards connect on a communication bus so modules can be added or removed easily. Custom PCB and custom firmware designed. Custom PC software developed to control precise movements of the setup. This is an example of early development stage of a complex machine which serves as a development platform.

Complex Functional Prototypes

Case Study: Diagnostic Analyzer

One-off high fidelity fully functional prototype of a diagnostic analyzer, with touch screen interface implemented. Plastics shaped to form the exterior body, treated and painted. Custom circuit boards, custom firmware developed. This is an example of a pre-production early phase display product that is great for investor showcase, trade exhibitions and to portray the future vision of the product.

Machine Design

Case Study: Cardboard Box Cutter

Designed using sheet metal and CNC metal, serviceability was high priority. Opening just 4 screws takes the top off for servicing. Uses off the shelf blades to keep running cost low. Custom circuit board and firmware, with multiple layers of software and sensor based safety implemented. This is a good example of a novel, purpose-built machine designed for low volume production.

Small Batch Production

Case Study: Camera Accessory

This small camera product was built with ease of firmware burning, keeping costs down and ease of assembly in mind. It features a tiny microprocessor. Snap fit plastic casing. Design for manufacturing done for both hard and soft plastics before sending for mold making. This is a great example of a low cost production run, for pre-production, testing the market, kickstarter projects etc.